Deburring and chamfering machines

Deburring and chamfering machines

Our burr machines efficiently perform one or more machining processes to remove burrs from workpieces and apply chamfers to the edges. Both internal and external gears can be precisely machined. Our burr machines can process a wide variety of components – from tiny workpieces with a diameter of just a few centimetres to huge components with a diameter of several metres. The workpieces can be processed either at one position or as a multi-spindle system at several stations.

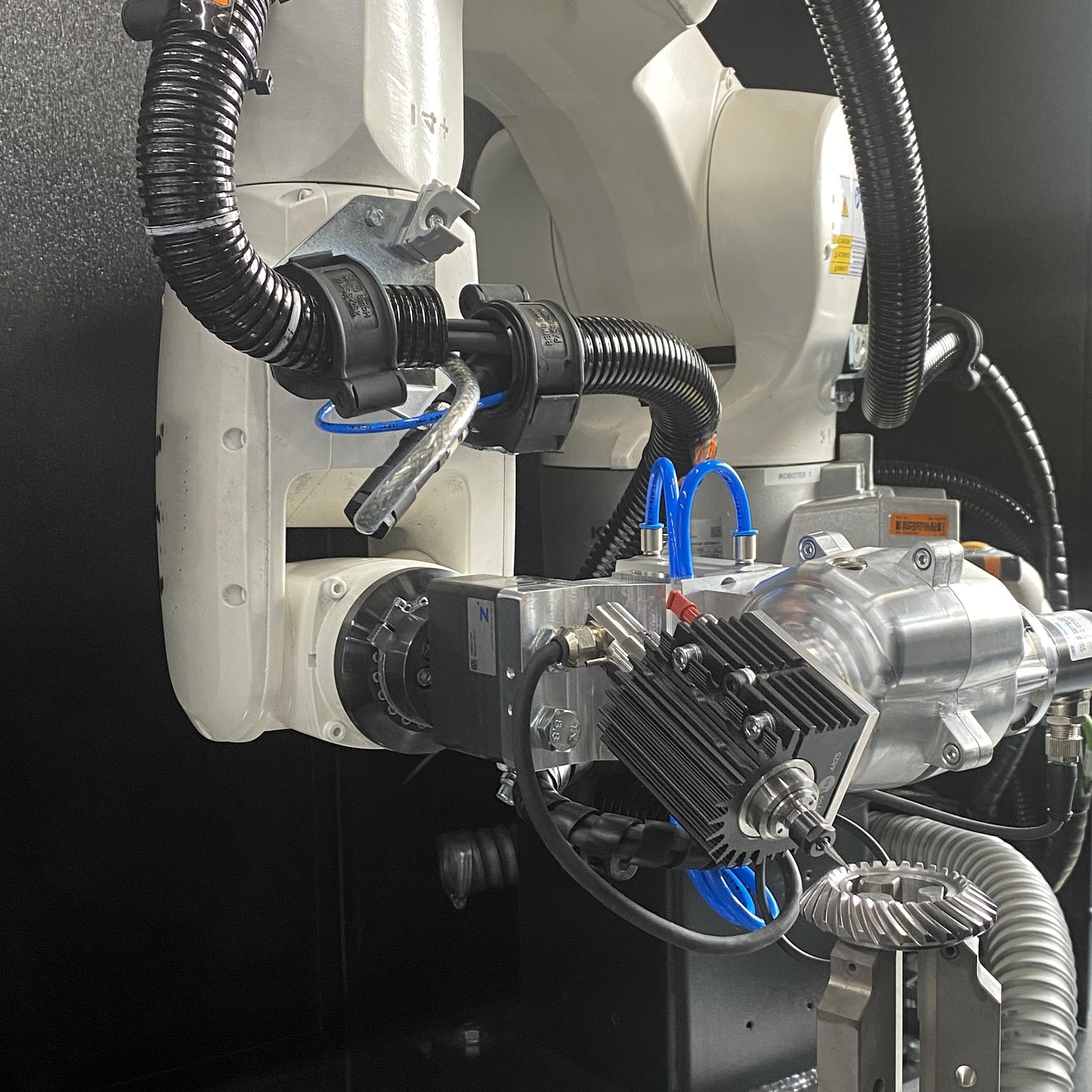

We use optional pre-deburring to break and remove coarse burrs, followed by machining the workpieces with grinding wheels or burrs. These are connected via compressed air or HF spindles to our innovative pendulum head, which guarantees a constant contact pressure and therefore an optimum chamfer on the workpieces. Finally, a secondary burr can be removed with a brush.

Our Gratomats are available inverschiedenenVariants available

Standard Gratomats

for various diameters, with a processing station, manual set-up or optionally equipped with a robot and very short delivery times

Customised special machines

with one or more processing stations.

Flexibility and accuracy

Thanks to the additional use of robots and our newly developed pendulum head 2.0, optionally equipped with pressure and angle sensors, we achieve the highest degree of flexibility and accuracy and can therefore effortlessly machine gears in the range from module 0.6 to 30.

From manual to fully automated loading and unloading using lifting/rotary loaders, gantry loaders, conveyor systems for workpiece transport, workpiece magazines and robot interlinking, we offer comprehensive solutions for our customers’ requirements. Our automation is customised and developed to meet your individual needs.